Our glossary contains a lot of useful information and statements about electromagnetic compatibility (EMC) and shielding

Abrasion Resistance

Abrasion resistance describes the ability of a material to withstand surface wear caused by influences such as polishing, grinding, etc.

Absorption

Absorption generally refers to the absorption of a wave (e.g. electromagnetic waves), a single particle or a particle stream into a body or substance.

Aluminium

Aluminium is a chemical element with the element symbol Al and the atomic number 13. It is a comparatively soft metal. Since it is highly ductile, it can be easily rolled out to form thin foil. Aluminium is a very good electrical conductor.

Ampere

Ampere with the unit symbol A measures the strength of an electric current flowing through a conductor.

Attenuation

Attenuation or reduction of the intensity of an electric or magnetic field, voltage or current along a transmission path, usually expressed in decibels (dB).

Carbon

Carbon is a chemical element with the symbol C. In nature it occurs both chemically bound (e.g. hydrocarbon) and in pure form (e.g. diamond).

CE-Mark

European directives require products to bear a CE-Mark. The manufacturer thus assures that the product complies with all applicable European regulations and that it has been subjected to the prescribed assessment procedures. The CE-Mark does not necessarily have to be awarded by an independent testing and certification body.

Clip-On Gaskets

These springs have been developed for applications where adhesive seals must not be used due to high temperatures or other design considerations. The clamping system is suitable for sealing gaps between an EMC-protected door and the door frame and similar applications.

Compression Set

Compression set is a measure of how elastomers behave under long-term, constant compression set and subsequent relaxation. Especially for EMC seals made of elastomers, the permanent deformation is an important parameter. A compression set of 100% means that the body has been completely deformed. 0% means that the body has fully regained its original shape.

Conductive Dispense Gaskets

Electrically conductive dispense gaskets made of silicone, usually with Ag/Cu - filler.

Conductive Elastomers

Electrically conductive elastomer gaskets are an important group in the field of EMC shielding when an environmental seal is also required. They consist of an elastomeric binder (silicone or fluorosilicone), which is supplied with different fillers depending on the desired shielding performance and contacted materials (prevention of corrosion). Conductive elastomers are produced in sheets, as moulded parts, as extruded profile or by screen printing. Depending on the application and the desired sealing profile, sealing rings can be supplied either as moulded parts or as vulcanised round cord. Extruded round profiles can be produced with very small diameters and are therefore well suited for narrow-walled housings.

Conductive Foils

Conductive foils have a wide field of application in shielding technology. They are inexpensive and easy to handle. Often they are supplied with a conductive adhesive. Classical applications are the complete lining of small housings, the sealing of housing joints and seams, electrical contacting of non-solderable surfaces, shielding of cables as well as short-term use during EMC measurements to find leaks by simply pasting over questionable areas.

Conductive Paints

Electrically conductive paints for spraying or painting with different fillers.

Connectors

Connectors are used to disconnect and connect electrical cables. Many standardised connectors and matching components exist worldwide.

Contact Fingers (Clip-On)

Contact springs e.g. for use on printed circuit boards, which Feuerherdt can supply in many different designs.

Contact Rings

Contact springs with suitable geometry can also be individually assembled in ring form. The contact rings can be supplied spot-welded or open.

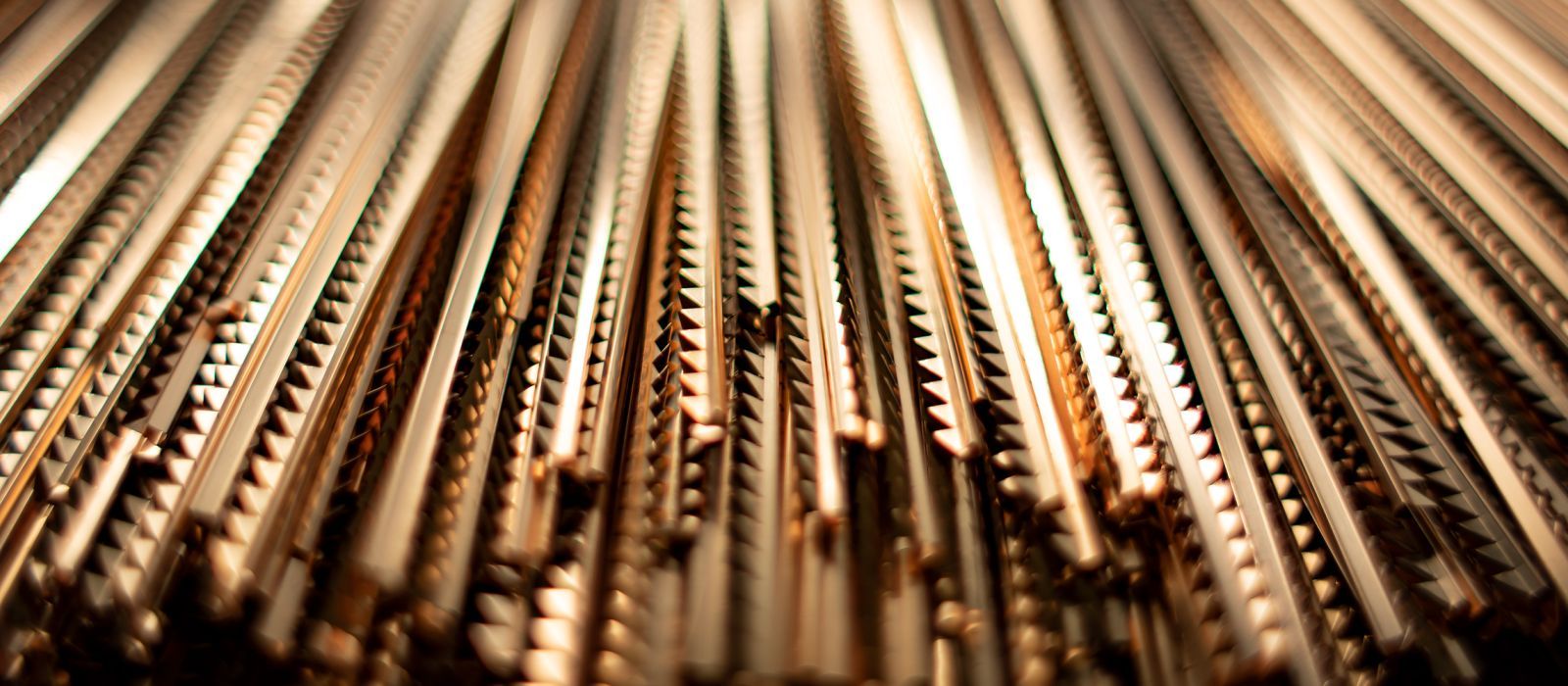

Contact Springs

Contact springs ensure by far the most effective shielding in all frequency ranges and are used in almost all branches of industry due to their excellent material properties. Copper-beryllium has the best physical properties, but Feuerherdt can alternatively supply a stainless steel version which, for example, offers better protection against extreme environmental influences.

Copper

Copper is a chemical element with the symbol Cu. It is a relatively light metal that is easy to shape and ductile. Copper is an excellent conductor of electricity and heat.

Copper Beryllium (CuBe)

Copper Beryllium or beryllium copper is an alloy of copper with 0.4 to 2% beryllium.

Copper beryllium alloys have excellent mechanical and electrical properties. The strength achieved after curing is by far the highest of all copper alloys, while at the same time high electrical conductivity is achieved. CuBe is extremely elastic and the perfect material for the production of EMC contact springs."

Corrosion

Corrosion is the reaction of a material with its environment, which causes a measurable change. This can lead to an impairment of the function of a component or system. The best known form of corrosion is the oxidation of iron, also called rusting.

Curved Fingers

Curved Fingers and Slippy Fingers are versatile shields that can be used to seal enclosures, cabinets and casings very effectively against interference radiation. The space required is small and installation is extremely simple, as the underside of the spring is equipped with double-sided adhesive tape. This means that time-consuming soldering, riveting or screwing work is not necessary.

The measured damping values are excellent. Magnetic field: At 14 kHz more than 46 dB. Free wave: At 10 GHz approx. 108 dB.

dB

dB, short for decibel, is the unit of power level LP, which describes the ratio of a power P compared to a reference power P0. LP = 10lg (P/P0) dB

Density

The density or mass density describes the ratio of the mass to the volume of a body.

Duo Seal

In critical environments, the task of using an environmental and an EMC seal can be solved with a Duo-Seal gasket. This seal consists of two materials with a vulcanised connecting seam. The material for the environmental seal is non-conductive silicone or fluorosilicone and protects the internal EMC seal from external contamination and moisture, thus preventing galvanic corrosion. The conductive part of the gasket can be filled with different materials such as silver/aluminium, nickel/graphite etc.

Elastomers

Elastomers are dimensionally stable plastics. These plastics can deform elastically under tensile and compressive loads, but then return to their original, undeformed shape. The compression set is an important parameter, especially for the use of EMC seals made of elastomers.

Electrically Conductive Adhesives

1-component silicone based adhesive that cures at room temperature. It is used in the field of high frequency shielding for elastic and electrically conductive bonding of HF gaskets, metal plates and foils.

Electromagnetic Interference (EMI)

Electromagnetic interference (EMI) is a signal or emission of magnetic and electric fields that affects the functionality of certain devices. Due to electromagnetic activities, electronic equipment emits emissions that can interfere with other electronic equipment. These interferences should be avoided by proper EMC shielding.

EMC

EMC is the abbreviation for electromagnetic compatibility and is defined in the European EMC Directive 2014/30/EU as follows: The ability of an apparatus, installation or system to function satisfactorily in its electromagnetic environment without causing electromagnetic disturbance itself which would be unacceptable to any apparatus, installation or system present in that environment.

EMC Act EMC Act refers to the law on the electromagnetic compatibility of equipment which is designed and manufactured in accordance with the generally recognised rules of technology in such a way that the following conditions are fulfilled: Firstly, the electromagnetic interference caused by the equipment must not make it impossible for other equipment to operate. Secondly, the equipment itself must be sufficiently insensitive to interference from other equipment.

EPDM

EPDM stands for ethylene propylene diene monomer and is a chemically cross-linked elastomer. It is characterised by very good electrical properties, good resistance to UV, ozone, acids and mechanical stress and excellent flexibility at both low and high temperatures.

ESD

ESD stands for "electrostatic discharge". This discharge is a spark that causes a very short high current pulse. In electronics, the electrostatic charge of the human body plays a particularly important role. The discharge can damage or destroy devices, electronic parts or components.

Extrusion

In extrusion, a solid to viscous and hardenable mass is continuously pressed out of a shaping opening under pressure. In the process, bodies with the cross-section of the opening in any length are created. Among other things, elastomer profiles are produced in this way.

Fabric over Foam Gaskets

Fabric over foam gaskets are made of an elastic foam core which is bonded to conductive fabric. Metallized conductive fabric bonded to the elastic core provides good EMC shielding and acts as a seal against air, light and dust. Profiles are also available with UL94-V0 specifications.

Fluorosilicone

Fluorosilicones are particularly temperature and oxidation resistant silicones. They have a high chemical resistance, are insoluble in water, hydrocarbons and chlorinated hydrocarbons and are stable between -60 and +290 °C.

Graphite

Graphite is a common mineral and one of the manifestations of the chemical element carbon. Graphite is hard and has very good electrical conductivity.

Grounding and Shielding Springs

Contact springs which can be glued, mounted or soldered as ground contact or for shielding.

GS Mark

The GS mark (Tested Safety) confirms that a product complies with the requirements of the Equipment and Product Safety Act. In order to be allowed to use the GS mark, the product must be tested and certified by an approved test centre.

Hardness

The term hardness refers to the mechanical resistance that a material offers to the mechanical penetration of a softer, equally hard or harder test specimen. The hardness can be determined by comparing several materials or material conditions.

Hertz

Hertz with the unit symbol Hz is the unit of measurement for the frequency of alternating current.

HF-Radiation

High-frequency electromagnetic waves are emitted for the wireless transmission of data in frequencies between 100 kHz and 300 GHz. Electric and magnetic fields merge to form an electromagnetic wave.

High-frequency radiation is used by radio and television stations, radar systems, mobile and cordless phones, microwaves and baby monitors. The reason for this is the rapid propagation of their waves and the long range of high-frequency radiation.

I/O Shield

I/O shield (also ATX shield, I/O shield or connector panel) refers to a PC component that closes the spaces around the rear external connectors of a mainboard, thus ensuring electromagnetic shielding and minimising dust exposure inside the computer. If several USB devices are to be connected, an I/O shield is required, otherwise interference may occur.

IEC

IEC stands for International Electrotechnical Commission. This international commission is responsible for standardisation in the field of electrical engineering and electronics.

Insulation

Insulation is the prevention of the passage of electrical currents by means of non-conductive materials. These insulating materials or insulators are non-conductive because they contain no or only isolated conduction electrons. These include, for example, certain plastics or glass.

IP

Electronics are also often exposed to harsh environmental conditions such as moisture, dirt or dust. The IP protection classes describe to what extent a component can be exposed to such conditions without posing a safety risk or being damaged.

The IP protection classes according to DIN 40050 are given in the format IPxx.

The first digit describes the protection against foreign bodies and contact, the second digit the protection in case of contact with water.

Below is an overview of the protection classes according to VDE 0710 DIN 40050:

1. code number: protection against foreign bodies and contact

0: not protected

1: Protection against ingress of solid foreign bodies with a diameter > 50 mm

2: Protection against ingress of solid foreign bodies with a diameter > 12.5 mm

3: Protection against penetration of solid foreign bodies with a diameter > 2.5 mm

4: Protection against penetration of solid foreign bodies with a diameter > 1 mm

5: dust protected

6: dust-tight

2. code number: protection against water

0: not protected

1: Protection against vertically falling dripping water

2: Protection against falling dripping water when housing is inclined up to 15

3: Protection against falling spray water up to 60° from the vertical

4: Protection against water spray from all sides

5: Protection against water jets

6: Protection against powerful jets of water

7: Protection against temporary immersion

8: Protection against prolonged immersion

9: Protection against high-pressure/steam jet cleaning

ISO 14001

ISO 14001 is an environmental management system introduced in 1996. The topic of environmental protection is systematically incorporated into management. Environmental aspects are thus taken into account in all company policy decisions and daily tasks.

ISO 9001

EN ISO 9001 defines the minimum requirements for a quality management system that an organisation must meet in order to provide products and services that meet customer expectations and regulatory requirements. At the same time, the management system should be subject to a continuous improvement process.

With the introduction of a quality management system in the company, the basis for systematic process sequences, plannable quality and a continuous improvement process shall be created. The most important goals of ISO 9001 are to increase the profitability of a company through efficient processes, to improve practical relevance and customer orientation and to reduce risks. A certified company can provide proof of minimum quality by this independent confirmation of certain standards.

Knitted Fabric

Knitted fabric refers to the arrangement of crossing wires or yarns. For example, a knitted wire mesh can be used excellently for EMC shielding.

Knitted Mesh Soft Gaskets

Knitted mesh soft gaskets have been specially developed for applications where very low clamping forces are required. A layer of Monel wire mesh over a very soft urethane foam provides good EMC shielding with excellent mechanical properties.

Kombi-Shield

Kombi-Shield consists of a mesh or mesh elasto gasket, which is laterally connected to a foamed or solid elastomeric gasket. The combination of mesh or mesh elasto with an outer strip of elastomer provides both good EMI/EMP shielding and good protection against dust and water.

Low Compression-Force Gaskets

Low compression-force gaskets are knitted fabrics made of silver-plated nylon yarn combined with a core of neoprene. They are characterised by the fact that excellent EMC shielding and a seal against dust and water can be achieved at low closing forces.

Low Profile Gaskets

Adhesive contact springs for special applications with small gaps that require low closing forces. Also available as a hook-in version.

Mesh Gaskets

Mesh gaskets made of metal wire, e.g. Monel, Tinned & Copper plated steel wire, stainless steel, copper beryllium, tinned copper or aluminium. Mesh gaskets are, depending on structure and design, comparatively flexible, offer good shielding performance and have no temperature limits.

Mesh-Elasto

The mesh-elasto gasket is a combination of EMC and environmental shielding. It consists of a round or rectangular elastomer core (silicone foam or hose, neoprene) and is knitted with wire in one or more layers. The elastomer core has a high recovery force and seals against dust and moisture. The knitted wire mesh provides EMC shielding.

Mesh-Tapes

Woven tape made of metal wire, which is used for shielding and grounding of cables in the electrical and electronic sector. Cf. mesh seal.

Monel

Monel is a nickel-copper alloy of approximately 65% nickel, 33% copper and 2% iron. Because of its high nickel content, Monel provides an excellent electromagnetic shielding effect. In addition, Monel is characterised by high tensile strength and corrosion resistance and is regarded as the precursor of stainless steel.

Nickel

Nickel is a silvery-white metal with the element symbol Ni, which belongs to the transition metals. Nickel is ferromagnetic and is highly resistant to air, water, hydrochloric acid and alkalis. Nickel serves as a coating metal for corrosion protection ("nickel plating") of metal objects. Because of these oxidation-protective properties, metals are coated with a layer of nickel for certain applications by electroplating.

Polyester

Polyesters are very versatile plastics from which a wide variety of objects can be made: from textile fibres to PET drinks bottles, CDs and packaging materials.

Polyolefin

Polyolefins are the most important subgroup of plastics. The best known representatives of this group are polyethylene and polypropylene.

Polyurethan

Polyurethanes are plastics or synthetic resins, which can be soft and elastic or brittle and hard, depending on how they are produced. Polyurethane can easily be used to make foams, but also, for example, lacquers, adhesives, coatings or elastic fibres.

REACH

Since 01 June 2007, Regulation No. 1907/2006 (REACH Regulation) of the European Parliament and the Council has been in effect and applies to all EU member states. It is a chemicals regulation for the registration, evaluation, authorisation and restriction of chemical substances. Substances that are placed on the market within the scope of REACH must be registered beforehand.

RoHS

Since 01.07.2006 the directive 2002/95/EC (RoHS directive) has been in effect. It applies in all EU countries and restricts the use of certain hazardous substances in electrical and electronic equipment. According to the RoHS directive, the products must be free of:

- Mercury (Hg)

- Lead (Pb)

- Cadmium (Cd)

- Hexavalent chromium (Cr VI)

- Polybrominated biphenyl (PBB)

- Polybrominated diphenyl ether (PBDE)

- Decabromodiphenyl ether (DecaBDE)

Shielded Windows

Glass or polycarbonate windows interspersed with mesh fabric for displays or shielded rooms.

Shielding Attenuation

Shielding attenuation is a measurand which quantifies the effectiveness of a shielding in terms of electromagnetic compatibility. The shield takes on the function - e.g. according to the principle of Faraday's cage - of protecting a spatial area which it surrounds from an external electrical field. The exact effectiveness is determined by the shielding attenuation.

Shielding Material

Today we can choose from a wide range of shielding materials. Starting with contact springs made of copper beryllium, through to plastics interspersed with conductive particles, to plastics or elastomers covered with knitted wire mesh. When it comes to making the appropriate selection, shielding effectiveness, contact pressure, mechanical and climatic conditions and, last but not least, the compatibility of the materials must be taken into account.

Shore Hardness

The Shore hardness, developed in 1915 by the American Albert Shore, is a material parameter for elastomers and plastics. It is defined in the standards DIN EN ISO 868, DIN ISO 7619-1 and ASTM D2240-00.

The hardness measuring method is carried out with a spring-loaded test probe, which can penetrate the material to be tested by a maximum of 2.5 mm. The measure for Shore hardness is the penetration depth, with a scale ranging from 0 Shore (2.5 mm penetration depth) to 100 Shore (0 mm penetration depth), with 100 Shore corresponding to the greatest hardness.

Silicone

Silicone is a name for a group of synthetic polymers in which silicon atoms are linked via oxygen atoms. Due to their typical inorganic structure on the one hand and their organic residues on the other hand, silicones occupy an intermediate position between inorganic and organic compounds, especially between silicates and organic polymers. They are hybrids to a certain extent and exhibit a unique spectrum of properties that is not matched by any other plastic.

Silicone Gaskets with Electrically Conductive Coating

These are soft gaskets with good shielding properties. Silicone round profiles are used as basic material: The electrically conductive coating of the outer skin is made with Ag/Cu. Technical data of the coating:

Volume resistance: 0.008 ohm-cm, coating thickness: 0.15 mm + 0.05, density DIN 53479: 3.6 g/cm3, elongation at break: 125%, temperature resistance: 125° C

Silver-Plated Glass

Silver-plated glass, which is incorporated into electrically conductive elastomers in the form of conductive particles.

Slippy Fingers

Slippy fingers are a further development of the curved fingers, in which the free part of the finger is guided in a flap and thus protected against damage. Depending on the pressure, the finger can more or less slip into the flap.

Slot-Mount Shields

Slot-mount shields or snap-on contact springs have a very low compression force, generate almost no friction when pressed together and are ideal for sliding applications. The symmetrical design enables a two-way contact. Suitable for mounting on rails or directly on the mounting plate.

SMD

SMD is the abbreviation for "surface-mounted device".

SMD components can be soldered directly onto a printed circuit board using solderable connection surfaces.

Spiral Shield Gaskets

Spiral shields are wound from spring hard copper-beryllium and stainless steel and are characterised by excellent fatigue strength and elasticity. If the copper-beryllium spiral is additionally tin-plated, it also provides excellent corrosion protection when in contact with aluminium in saline environments. Stainless steel shields are used when the focus is on corrosion protection and not on the conductive properties.

Stainless Steel

Stainless steel is the designation for alloyed or unalloyed steel with a special degree of purity.

Stainless steel has a very good corrosion resistance due to a passive layer which acts as a barrier between the alloy and the media surrounding it. If the passive layer is damaged, it automatically restores itself under the influence of oxygen.

Twisted Contact Strips

Contact spring for EMC shielding applications where there is a narrow opening or gap. The self-adhesive tape makes installation easy and safe.

UL 94

Regulation UL94 "Tests for Flammability of Plastic Materials for Parts in Devices and Appliances" from Underwriters Laboratories (UL) describes a method for evaluating and classifying the flammability of plastics. It has been adopted in the IEC/DIN EN 60695-11-10 and -20 standard with the same content.

The following classes are distinguished:

HB: a horizontally clamped sample burns slowly

- V-2: a vertically clamped sample extinguishes within 30 seconds

- V-1: same as V-2, but no burning dripping of plastic melt allowed. Maximum 60 seconds afterglow.

- V-0: same as V-1, but flame extinguishes within 10 seconds. Maximum 30 seconds afterglow.

There are very similar classifications for foams (HF-1, HF-2, HBF) and thin films (VTM-0, VTM-1, VTM-2).

VA Steel

VA is a synonym for stainless steel. Further designations for VA steel are e.g. high-grade steel, premium steel, special steel, high quality steel, Inox, Cromargan (trade name of WMF) or Nirosta (brand name of Outokumpu Nirosta, formerly ThyssenKrupp Nirosta).

Stainless steel is characterised by good spring properties, very good shielding properties and resistance to corrosion and acids. For contact springs Feuerherdt generally uses stainless spring steel with the material number 1.4310.

Vulcanisation

Vulcanisation is a chemical process in which thermoplastic natural or synthetic rubbers are converted into elastomeric plastics. During vulcanisation, covalent cross-links are formed between the macromolecules of the rubbers so that the molecules can no longer move freely against each other. This gives rubber its permanently elastic properties and makes it suitable for industrial use.

We will be happy to answer further questions at emc@feuerherdt.de or +49 30 710 96 45 50