All Metal Gaskets (Knitted Wire Mesh)

Description | Mechanical tolerances: | |||||||

All metal gaskets are available in four designs: round, rectangular, | 1,5 - 5 mm | +0,4 -0,0 mm | ||||||

10 - 5 mm | +0,6 -0,0 mm | |||||||

>10 mm | +0,8 -0,0 mm | |||||||

Round

Part-No. | Ø |

2001.XXYY.016 | 1,60 |

2001.XXYY.024 | 2,40 |

2001.XXYY.032 | 3,20 |

2001.XXYY.048 | 4,80 |

2001.XXYY.064 | 6,40 |

2001.XXYY.080 | 8,00 |

2001.XXYY.095 | 9,50 |

2001.XXYY.111 | 11,10 |

2001.XXYY.127 | 12,70 |

2001.XXYY.159 | 15,90 |

2001.XXYY.191 | 19,10 |

XXYY: Basic material and finish, see material table Ⓜ

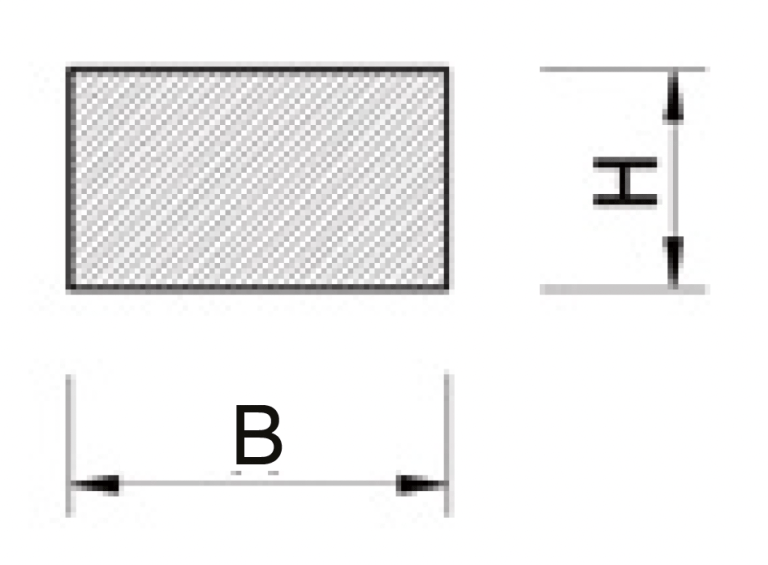

Rectangular

Part-No. | Height | Width |

2004.XXYY.024.024 | 2,40 | 2,40 |

2004.XXYY.024.048 | 2,40 | 4,80 |

2004.XXYY.024.064 | 2,40 | 6,40 |

2004.XXYY.032.032 | 3,20 | 3,20 |

2004.XXYY.032.064 | 3,20 | 6,40 |

2004.XXYY.032.080 | 3,20 | 8,00 |

2004.XXYY.048.048 | 4,80 | 4,80 |

2004.XXYY.048.080 | 4,80 | 8,00 |

2004.XXYY.048.127 | 4,80 | 12,70 |

2004.XXYY.064.064 | 6,40 | 6,40 |

2004.XXYY.064.127 | 6,40 | 12,70 |

2004.XXYY.080.127 | 8,00 | 12,70 |

2004.XXYY.095.127 | 9,50 | 12,70 |

XXYY: Basic material and finish, see material table Ⓜ

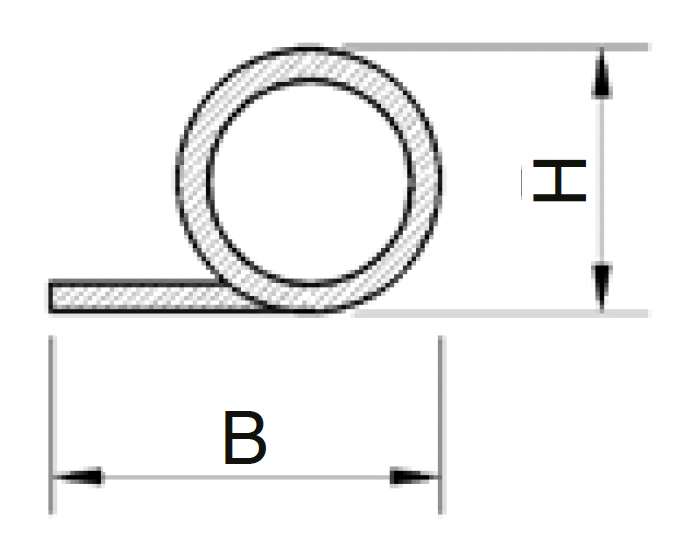

Round with Mounting Fin

Part-No. | Height | Width |

2005.XXYY.016.127 | 1,60 | 12,70 |

2005.XXYY.024.159 | 2,40 | 15,90 |

2005.XXYY.032.095 | 3,20 | 9,50 |

2005.XXYY.032.127 | 3,20 | 12,70 |

2005.XXYY.040.127 | 4,00 | 12,70 |

2005.XXYY.040.195 | 4,00 | 19,50 |

2005.XXYY.048.127 | 4,80 | 12,70 |

2005.XXYY.048.191 | 4,80 | 19,10 |

2005.XXYY.064.159 | 6,40 | 15,90 |

2005.XXYY.064.191 | 6,40 | 19,10 |

2005.XXYY.080.159 | 8,00 | 15,90 |

2005.XXYY.095.195 | 9,50 | 19,50 |

2005.XXYY.127.254 | 12,70 | 25,40 |

XXYY: Basic material and finish, see material table Ⓜ

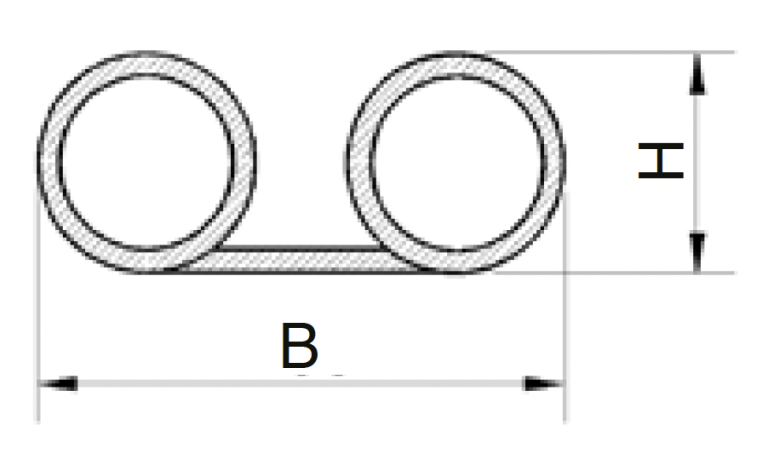

Double Round with Mounting Fin

Part-No. | Height | Width |

2006.XXYY.032.095 | 3,20 | 9,50 |

2006.XXYY.032.127 | 3,20 | 12,70 |

2006.XXYY.032.159 | 3,20 | 15,90 |

2006.XXYY.032.191 | 3,20 | 19,10 |

2006.XXYY.040.254 | 4,00 | 25,40 |

2006.XXYY.048.191 | 4,80 | 19,10 |

2006.XXYY.048.222 | 4,80 | 22,20 |

2006.XXYY.048.254 | 4,80 | 25,40 |

2006.XXYY.064.191 | 6,40 | 19,10 |

2006.XXYY.064.254 | 6,40 | 25,40 |

2006.XXYY.080.222 | 8,00 | 22,20 |

2006.XXYY.095.254 | 9,50 | 25,40 |

2006.XXYY.095.320 | 9,50 | 32,00 |

XXYY: Basic material and finish, see material table Ⓜ

Material

Basic material and finish (XXYY) | |

2502 | Monel |

2407 | Tinned copper-clad steel wire |

2202 | Stainless Steel |

2002 | Beryllium copper |

2130 | Tinned copper |

2302 | Aluminium |

On request available in 2-layer or 2-threaded version.

Monel

Material No. (DIN) 2.4360

Wire Diameter 0,11 mm

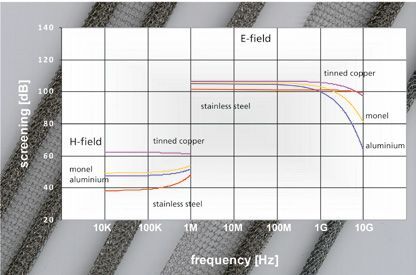

Shielding Effectiveness Electrical | ||

Frequency (Hz) | Mode | Screening (dB) |

1 M | E | 124,5 |

10 M | E | 110 |

110 M | P | 105,5 |

400 M | P | 101 |

1 G | P | 86 |

10 G | P | 82,5 |

Magnetic | ||

| 10 K | H | 36 |

| 100 K | H | 42 |

| 1 M | H | 48 |

Tinned, copper-plated steel wire

ASTM-B-520

Wire Diameter 0,11 mm

Shielding Effectiveness Electrical | ||

Frequency (Hz) | Mode | Screening (dB) |

1 M | E | 125,5 |

10 M | E | 110 |

110 M | P | 114,5 |

400 M | P | 99 |

1 G | P | 85,5 |

10 G | P | 99,5 |

Magnetic | ||

| 10 K | H | 62 |

| 100 K | H | 62,5 |

| 1 M | H | 61 |

Stainless Steel

AISI 304, Material Nr. (DIN) 1.4301

Wire Diameter 0.11 mm

Shielding Effectiveness Electrical | ||

Frequency (Hz) | Mode | Screening (dB) |

1 M | E | 119,5 |

10 M | E | 104 |

110 M | P | 103,5 |

400 M | P | 97 |

1 G | P | 84 |

10 G | P | 101,5 |

Magnetic | ||

| 10 K | H | 36 |

| 100 K | H | 42 |

| 1 M | H | 48 |

Aluminium

Alloy 5056, AMS-4182

Wire Diameter 0.13 mm

Shielding Effectiveness Electrical | ||

Frequency (Hz) | Mode | Screening (dB) |

1 M | E | 125 |

10 M | E | 111,5 |

110 M | P | 105 |

400 M | P | 98 |

1 G | P | 81,5 |

10 G | P | 65 |

Magnetic | ||

| 10 K | H | 45 |

| 100 K | H | 50,5 |

| 1 M | H | 51,5 |